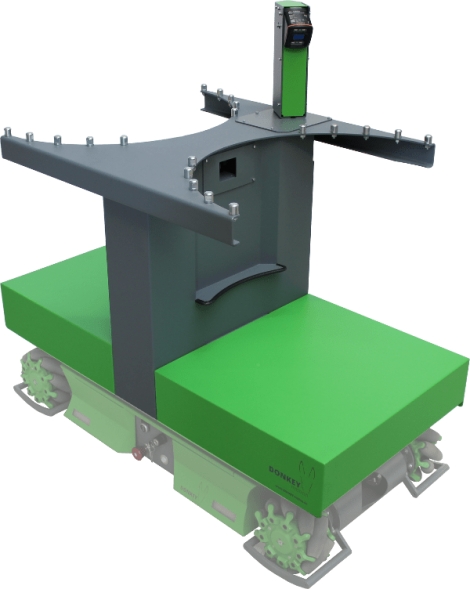

The driverless transport vehicle Donkey-S-HL-1206 independently transports empty and full buckets. Whether brass, aluminium or steel chips, the processing in the centrifuge can take place one after the other with different materials, the transfer of the chips to the centrifuge system is always sorted by type.

Another bonus: The DONKEY can be used flexibly in production, so all other intralogistical material flows can also be realised safely and driverless with the CALL THE DONKEY automated guided vehicle system.

Like our other load modules, this load module also contains the Li-Ion battery that supplies the Donkey-S-HL-1206 with energy. Thus, by switching between the load modules, the Donkey can continue to work 24/7 without any breaks due to charging. The chip level measurement ensures that only buckets that are not overfilled are fed to the chip disposal system, thus achieving a high process reliability of the chip disposal.

For adaptations of our load modules to your specific tasks, please contact our technical support.

Technical Data

- 1.200 x 600 x 940 mm (L x W x H)

- Chip payload net 200 kg

- 2 Holders for transporting round 120 l chip buckets

- Optical level measurement

- 2,0 kWh battery capacity

- Mass: 65 kg