Research and Development at imetron

It is no secret that Germany is a country of innovation and that products made "in Germany" are always in high demand. Small and medium-sized enterprises in particular contribute enormously to Germany's world-famous "innovative strength". imetron has also been investing heavily in the future for years: Formerly a pure manufacturing service provider, imetron has positioned itself as a sought-after technology company. In addition to its own product innovations, innovative development work is carried out and projected on behalf of customers.

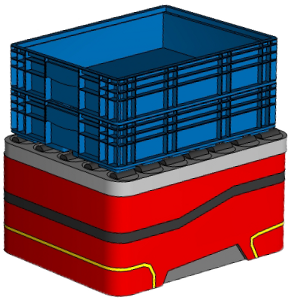

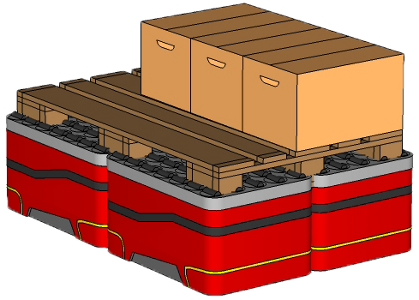

More specifically, we have specialised in the area of "Mecanum wheeled automated guided vehicles": With the DonkeyMotion modular system, the company offers an intelligent, modular product. The Mecanum drives are the result of a research project with Dortmund University of Applied Sciences and Arts. In order to always be able to include the current state of research in the development of future-oriented cutting-edge technology, further cooperations exist, such as those with the Institute for Materials Handling and Logistics at KIT (Karlsruhe) and the Institute for Computer Science at the University of Freiburg, as well as with renowned industrial partners, including Audi, Sick AG, and Bosch.

For example, imetron's developers are conducting intensive research in the field of "Automated Guided Vehicles of the Future" in three cooperation projects:

-

Project „KARIS PRO" – small-scale driverless transport systems

-

Project „Object protection"

-

Project „Mechanical and mechatronic development of omnidirectional driverless transport systems"

The German government's high-tech study forecasts a revolution in production in an "Industry 4.0" scenario. In the process, products are to become increasingly individualized so that tomorrow's efficient manufacturing process can offer maximum flexibility and individuality. A future-proof logistics system with these properties must be able to adapt quickly to diverse and changing requirements and spatial conditions. The DonkeyMotion modular system has the necessary features and can be used modularly and cost-efficiently.

The research projects focus, for example, on decentrally controlled transport systems that operate intelligently and autonomously, because they are networked with each other like a swarm. Safety laser scanners ensure safe operation, avoid collisions and control precise docking at transfer stations. Obstacles and people are detected in time. "KARIS PRO" is to become an innovative material supply system that offers self-organized and demand-based functions. The team led by Prof. Dr.. Ing. Furmans is researching the development of an omnidirectional robot controlled by a radio localization system in real time.

imetron experiences an immense increase in knowledge and experience through its involvement in several research projects, which would not be possible otherwise. As a small and agile company, it is able to quickly translate these findings into market-ready products.

Project KARIS PRO – Small-Scale Driverless Transport Systems

Conducted with the "Institute for Materials Handling and Logistics Systems" of the KIT in Karlsruhe under the direction of Prof. Dr. Ing. Kai Furmans.

KARIS PRO will be an innovative material supply system that supports new production approaches. Intuitively operable, humans can intervene in the self-organising system and prioritise task planning. The safety system guarantees a smooth process, and ergonomically coordinated functions support lifting operations by the worker, for example.

The swarm-like system organises itself and can be deployed as needed - even complex tasks can be realized in this way.

From individual transport to moving large parts, the material supply system can solve and take on a wide variety of tasks; the individual elements are able to cluster, combine and then unite to handle heavier transport tasks. All this is only made possible by the networking and interaction of the individual elements. The decentrally controlled elements make joint decisions regarding the type, time and location of task processing. The model for this was the swarm behaviour in the animal kingdom; as can be observed, for example, in the species of birds, the intelligence for solving tasks arises in the interaction of the swarm. The birds do not rely on a superior and leading authority.

The result will be a fault-tolerant, stable system that can be implemented quickly.

Project Object Protection

Material handling systems and service robots are to be used more and more in "public" flexible environments. Until now, the sensor system that detects hazards and obstacles three-dimensionally is still missing here. Today's systems are limited to a flat visual surface. Access by unauthorised persons in the system's area of operation must therefore be ruled out. imetron and the Institute for Materials Handling and Logistics Systems (IFL) at KIT are researching the development of a robust, simple, track-guided, and energy-efficient material flow system. A 3-D camera prevents all collisions, including those that may be caused by the load. In this way, a safe target-oriented material flow system with adaptive object protection and load securing for the transport of divergent load carriers can be achieved.

http://www.ifl.kit.edu/projekte_objektschutz.php

Project Mechanical and Mechatronic Development of Omnidirectional FTF

From 13 - 17 April, the results of this research project were presented at the Hanover Fair: „Automatische Navigation eines omnidirektionalen Transportfahrzeugs für Europaletten".

From 13 - 17 April, the results of this research project were presented at the Hanover Fair: „Automatische Navigation eines omnidirektionalen Transportfahrzeugs für Europaletten".

The localisation of the vehicle is done with Bluetooth Low Energy (BLE, iBeacon technology), spontaneous transports by handheld. The aim of the project in collaboration with Dortmund University of Applied Sciences and Arts, headed by Prof. Dr. Christoph Röhrig, is to develop omnidirectional driverless transport vehicles (AGVs) that can transport loads automatically and integrate into a complete driverless transport system (AGV).

The surface mobility in all 3 degrees of freedom is achieved by Mecanum technology. With outstanding navigability, even in confined environments, maximum surface mobility can be realised.

In this way, the new AGV will take over automated transport tasks in production and intralogistics that were previously controlled manually. Whereas with line-moving vehicles blocked lanes lead to a stop of the entire transport process, the AGV can bypass them and ensure a smooth process. A modular design of the vehicles guarantees a cost-efficient adaptation to changing logistics processes.