Whether island production, flexible assembly cell or one-piece flow assembly, the basic principle is always the same: The product is moved on cyclically and processed step by step in various assembly islands. The cycle is not set by the assembly line, but by the worker or the assembly team. In most cases, more flexibility and more varied workplaces are expected from this type of production. Today, tuning engines, washing machines or entire excavators are assembled according to this principle.

Whether island production, flexible assembly cell or one-piece flow assembly, the basic principle is always the same: The product is moved on cyclically and processed step by step in various assembly islands. The cycle is not set by the assembly line, but by the worker or the assembly team. In most cases, more flexibility and more varied workplaces are expected from this type of production. Today, tuning engines, washing machines or entire excavators are assembled according to this principle.

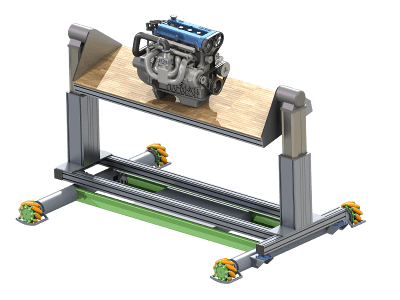

Mobile assembly platforms are needed for this. These mobile assembly platforms transport the workpiece, but also have other tasks such as lifting, rotating and swivelling or transporting tools. The Mecanum modular system is the ideal basis for flexible and economical assembly platforms:

- The Mecanum assembly platform can rotate with the workpiece on the spot. Optimum ergonomics, therefore, without an additional rotary table.

- The mobile assembly platform, moved by Mecanum wheels, can turn in the tightest of spaces when the assembly line turns a corner.

- If the products are buffered in an intermediate storage area, the storage space can be utilised with the highest packing density, as the mobile assembly platform can approach the storage location at right angles in the storage aisle.

- Our modular system allows the mobile assembly platforms to be constantly adapted to changing requirements. The compact drive units and the control boxes can be reassembled again and again. If, for example, more large excavators are unexpectedly manufactured in the future than small bucket loaders, the mobile platforms can be adapted to the requirements with little investment. Through "mutability", a big step towards Industry 4.0.

- ...

Ask us. We will be happy to advise you on the selection of our system components. Just as you wish, we can also realise your complete system. Whether only the planning or the turnkey assembly platform, you decide on the scope of our services!